The newcomer to oyster farming who embraced innovation & agtech in order to work a four-day week!

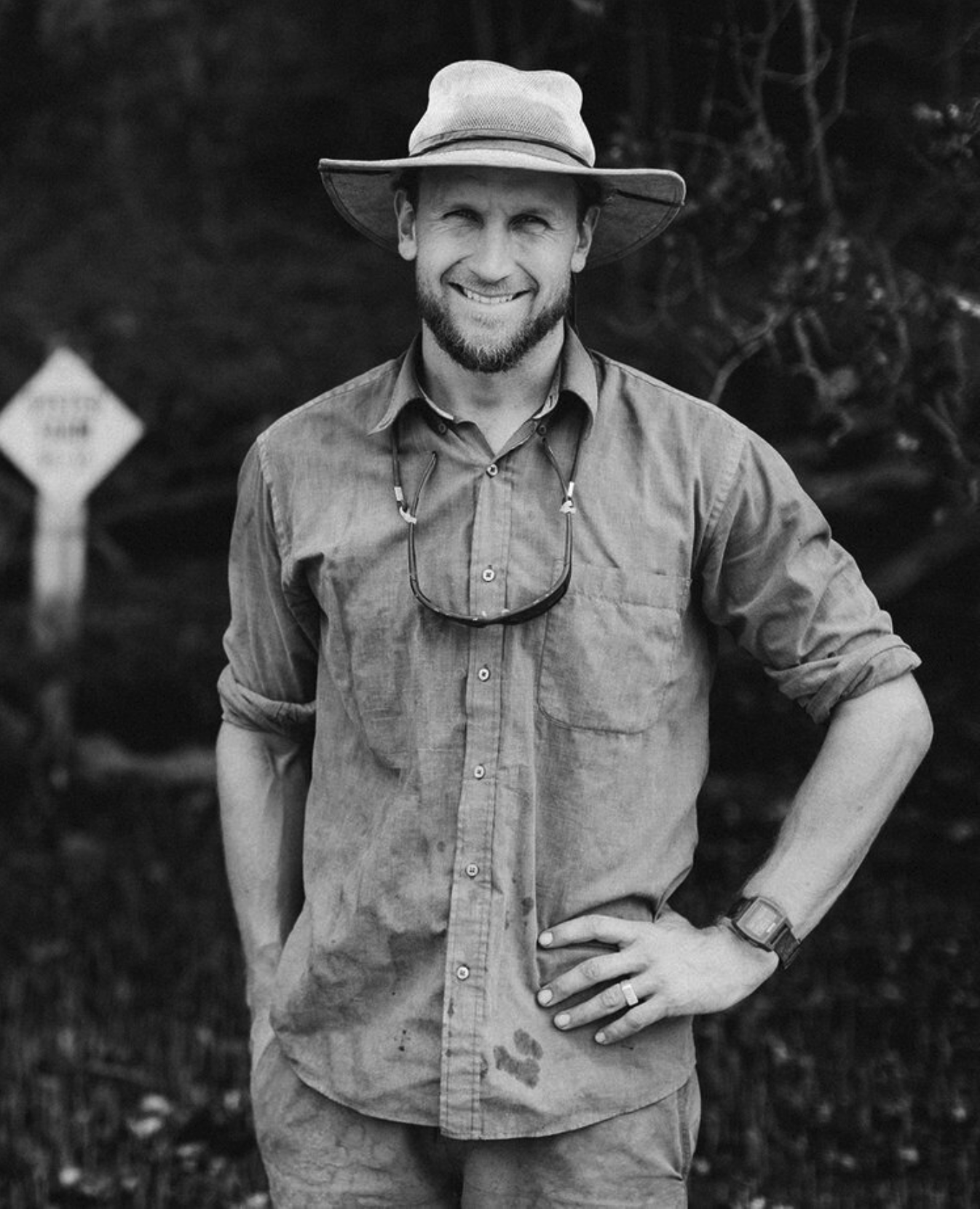

Meet Jase Finlay

The concept of even a five-day work week is unheard of for most farmers who frequently work their farms seven days straight. If they’re not physically present then they’re thinking about the farm; where it’s at, what’s been done, and what needs to be done next. Not Jase Finlay. The 34-year-old oyster farmer, from the south coast of NSW, only works a four-day week and is still kicking major farm goals. By embracing new innovative methods, such as agtech, he has been able to improve efficiencies and outsource the information in his head. This means he can switch off when not on the farm, and be present with his young family.

Jase Finlay on the farm (photo by OysterLife)

His isn’t the classic farmer story. Originally a pro-surfer, he trained as a high school teacher and was all set to make that his career until he met Ewan McAsh of McAsh Oysters (now OysterLife).

Jase Finlay - definitely not on the farm

“It was pure luck, I guess. I was set on my path when Ewan came into the family and he introduced me to the business. I trialed a day on the river and that was it. I was hooked,” Jase says.

“I’m just a really big nature man. I spent so many years traveling while surfing, that to suddenly be in a classroom all day wasn’t the right fit. I find a lot of relief and comfort being outdoors and part of the water.”

Jase was a sponge, picking up all he could. To him, he was learning how to be a farmer but he didn’t realise that what Ewan was really doing was training him up to take over.

“I was so fresh. I had fresh eyes coming into the industry and was motivated to try new things and improve efficiencies as much as possible. I was looking into all the new things that were popping up rather than having a fully formed idea of how you had to farm oysters,” he says.

“A few things steered us towards the four-day week. The biggest motivator was to keep family a priority in our lives. Ewan and I both have young children at the moment and wanted to be present at home with our families instead of thinking about the farm, tracking large numbers of oysters and where they are at and what needed to be done. Mentally scrolling through that information all the time was all consuming.

“We were able to pull back to a four-day week because the technology the farm was using allowed us to focus on what mattered. We weren’t consumed with time wasted trying to catch up with things that were missing. We simplified things so much that we could simply pass information to coworkers digitally to carry on the day-to-day operations when we are not there.

“In some ways I feel guilty knowing how many farmers are working seven days a week, but putting family first is the most important thing in my life and makes total sense. I plan on doing this for the rest of my life, balancing family and work is very fulfilling.”

Jase checking oyster quality on one of the farm's SEAPA lines

Among all the modern tools in use on his farm such as the SED visual grader, and gear such as SEAPA baskets, Jase credits three new tools in particular with allowing him that balance. The farm management platform - SmartOysters, the introduction of the ultra efficient new FlipFarm system, and live storage tanks.

“Our whole management system was essentially replaced with a digital version. Being a newbie into the industry, it made sense to me. All of the knowledge that Ewan has accrued over the years was now available to me via the app. Any workplace should be taking advantage of the efficiencies technology can bring.” he says. “For my first year farming we were using paper forms that would then be translated into spreadsheets, then printed off every second day and then corrected. There was no live information, there was a process of flicking through papers, making sure they didn’t get wet and spending time finding what we needed instead of having it at our fingertips.

“Within two weeks of using the new technology it was like a weight came off my shoulders. There were so many things I didn’t have to remember now. The technology meant that nothing was forgotten and I didn’t have to worry about it.

“Seeing land agriculture and the technology that they use, I assumed it was standard farming practice no matter which industry you went to, so I was surprised that previously there wasn’t anything like this available for aquaculture. Even at my age, I’m not part of the new tech generation, it seemed too far in the past to be still writing on boards and paper, I knew there was a better way, and thankfully I found it.”

The new FlipFarm system was also a game-changer. “It removes a lot of physical labour and handling and in turn, is quicker to use. It produces amazing oysters with a fraction of the effort,” Jase says.

“The labour component in oyster farming is huge, you’re only able to work as fast as your body can handle. When the physical labour is reduced and a system takes over that burden, you can achieve so much more in the day. You’re more energised and flying through what would usually drag you down.

“There are definitely parts of the system where we've almost quadrupled the efficiency.

“The new system simplified operations in terms of not as much needs to be brought back into the shed. The baskets remain on the line and you simply transport the oysters to and from them for grading. This also means that empty baskets are stored on the lines out on the water rather than taking up valuable space in the shed. It's a major time saver all round.”

The third tool that Jase has embraced is live oyster tanks.

“Besides the obvious and having live oysters ready to use in times of any river closures, the biggest advantage is the separation of roles,” he says.

“From a grader’s perspective, as soon as an oyster leaves the grading shed then it’s sold. Once it’s in the live tank, the sales team are pushing and driving that part of the business. Our job is done and we can go onto the next task.”

The separation of roles in this manner allows each team member to truly focus on their role and has accelerated the farm's growth significantly.

To read more about the live tanks, click here.

To learn more about Jase and the amazing OysterLife story, please click here.

Jase living the dream...